How American Plastics can Save You Time, Stress, and Money.

The Basic Principles Of American Plastics

Table of ContentsThe Ultimate Guide To American PlasticsAmerican Plastics Things To Know Before You Get ThisAn Unbiased View of American PlasticsSome Of American PlasticsAn Unbiased View of American Plastics

A little homework can assist you over time. It is difficult to evaluate its high quality in the beginning glimpse with the appearance of HDPE pipe installation, several issues are subjected when using, so we can just have an appropriate judgment after usage. For that reason, it is needed to pick HDPE pipeline fittings made by a professional producer with a good credibility and reputation.A technological expert is essential for an excellent item, specifically in the manufacturing sector, due to the fact that a tiny blunder will result in the failure of the entire project. HDPE pipes can change concrete pipes in field systems to conserve time and price of repairing broken or burst pipes. HDPE pipe is additionally a more economical choice contrasted to various other piping materials in regards to operating and installment costs.

The Best Strategy To Use For American Plastics

HDPE pipes are manufactured with strong straight or rounded sections. It is constructed from lightweight materials that are easy to transport and does not need heavy setup tools such as hefty cranes. The combination of lightweight and flexible frameworks makes it optimal for earthquake-prone areas. The pipelines are not weak and can be quickly inserted right into a bent location without additional jointing or welding.

Chemicals resistant to HDPE pipes can infect the pipe. The pipeline does not function with chemicals and does not shed heat or power.

HDPE pipelines are naturally solid and immune to damage brought on by external tons, high stress or vibration - https://slides.com/americanplastics. The pipelines can endure handling and bend also in winter. Safe eyeliner HDPE internal tubing Smooth Line Pipe Sliding lining making use of roller mixes Pipeline explosion Plastic plumbing systems Building and construction of new pipelines Corrosion resistance, no dripping, high durability

Heat integration, while its obstacles exist, can develop solid and reputable joints. Responses: The toughness and toughness of HDPE can be determined by its capacity to hold up against temperature levels of around 248F in the short term or even a continuous 230F. If your application consists of gas and liquid to gain access to and increase those temperatures, HPDE piping is a reliable remedy.

Little Known Facts About American Plastics.

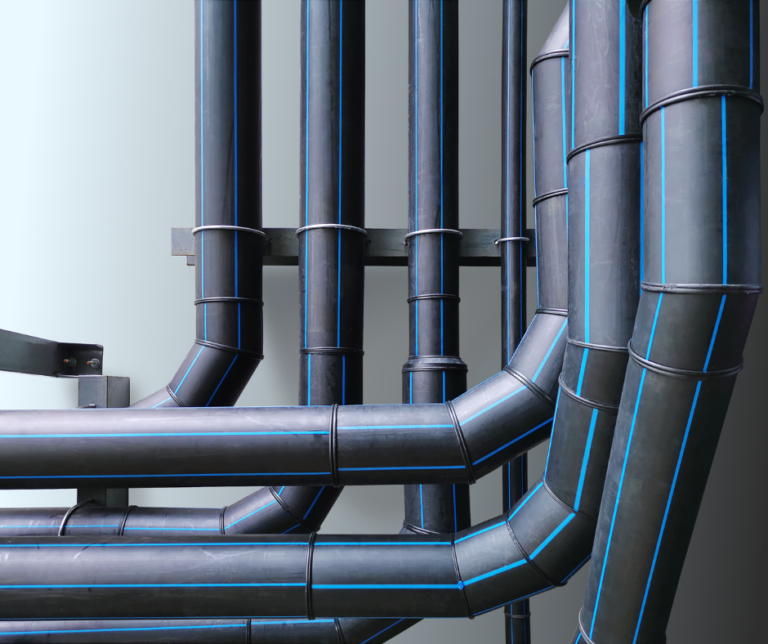

For instance, a potable water line/potable pipes is always dark with blue stripes and pipes passing through liquids, liquids under stress, and procedure gases are always loaded with a yellow or black coat with yellow lines. HDPE pipe material have been made use of in the general market for over 50 years and their outcomes are remarkable, building confidence among producers that they are extra concentrated on HDPE pipe services.

Times because 1991 Elimination of resin needs with scale and adjustment. In the tension crack resistance examination the cellular division requirements were compromised. It is practical to conclude that HDPE pipe constructed today may have.

Each dimension classification is designed bearing in mind the demands of stress, flow rate, and environmental factors of the intended application. By matching the correct HDPE pipeline size to its usage, designers and service providers can maximize performance and expand the life-span of their piping systems. Dimension and size are related ideas in the context of HDPE pipelines.

Facts About American Plastics Uncovered

As mentioned earlier, pipes with reduced SDR worths are able to endure greater pressures, which is an essential factor to consider in the option process for projects that include high stress or crucial applications. hdpe pipe fittings Midland TX. Picking a pipe with an inappropriate SDR might result in system failing, security threats, and costly repair services. Selecting the appropriate HDPE pipeline dimension is crucial for the success and effectiveness of any kind of piping system

Application Specifics: Customize your pipeline size choice to the certain requirements of its application, whether for local, industrial, or various other uses. Recognizing how the HDPE pipe will certainly be used, the expected circulation prices and the pressure demands are critical. High-pressure applications might require a pipe with a greater wall thickness to stand up to the interior stress and anxieties, while a lower-pressure, high-flow system may focus on diameter size to decrease friction loss.

8 Easy Facts About American Plastics Explained

Comply with these actions: Assess the Application: Identify the pipeline's planned usage, including ecological variables and service conditions. Refer to SDR: Inspect the basic measurement proportion to discover a pipe that can manage the required pressure.

Picking the best HDPE pipe dimension is a fragile balance in between countless technical requirements and sensible requirements - https://allmy.bio/ffm8rfo. With mindful factor to consider and exact click estimations, you can ensure the size of the pipeline you select will serve your requirements properly and successfully. Choosing the proper HDPE pipe dimension is vital for system effectiveness, resilience, and cost-effectiveness

Understanding these facets will certainly make certain ideal performance and compatibility throughout your piping system - Texas hdpe pipe manufacturer. The awaited flow rate or quantity of the fluid being delivered is just one of the main factors in pipe size selection. A pipeline that is as well tiny can limit circulation, creating stress loss and potential blockages, while an excessively big pipe might cause unnecessary cost and decreased system effectiveness